Imagine walking into a factory where heavy machinery is humming, and robots are gliding smoothly, executing precise tasks without a hitch. Yet, what happens when your grip fails at the critical moment? It’s a real headache, ’cause that’s the pain point many face. This is where the electric gripper comes into play, revolutionizing how we handle materials. It’s all about boosting efficiency and reliability—two non-negotiables in today’s fast-paced production lines.

Traditional Solutions & Their Flaws

Let’s face it—manual gripping methods or pneumatic solutions can be a hassle. They’re often slow, require maintenance, and sometimes just can’t handle the job. Friction, wear and tear, and inconsistent grip strength are major drawbacks, leading to production delays and costs skyrocketing. Remember that time you lost a crucial component because of a faulty grip? We’ve all been there—it’s frustrating!

New Technology Principles of Electric Grippers

So, what’s the deal with electric grippers? Well, they use electric actuators that provide precise control over grip strength and speed. This means no more air leaks or constant upkeep. These grippers utilize smart sensors, improve adaptability, and are super efficient—think edge computing nodes right at your fingertips! Whether in highly regulated environments like medical or dynamic manufacturing setups, they’re a game-changer.

Quantified User Benefits

Did you know that users are reporting up to 30% higher efficiency rates? That’s no small feat! With electric grippers, companies are also seeing significant reductions in downtime. It’s not just about speed; the consistency of grip translates to fewer product flaws and reduced waste. In turn, this leads to enhanced profit margins and increased customer satisfaction. Get ready—this is a new era of automation!

Conclusion: Time for Action

Before you dive headfirst into solutions, always verify these 3 metrics when choosing: ① efficiency in operation ② adaptability to your specific needs ③ overall reliability. These checkpoints are essential for not only better performance but also for seamless integration into your existing setups.

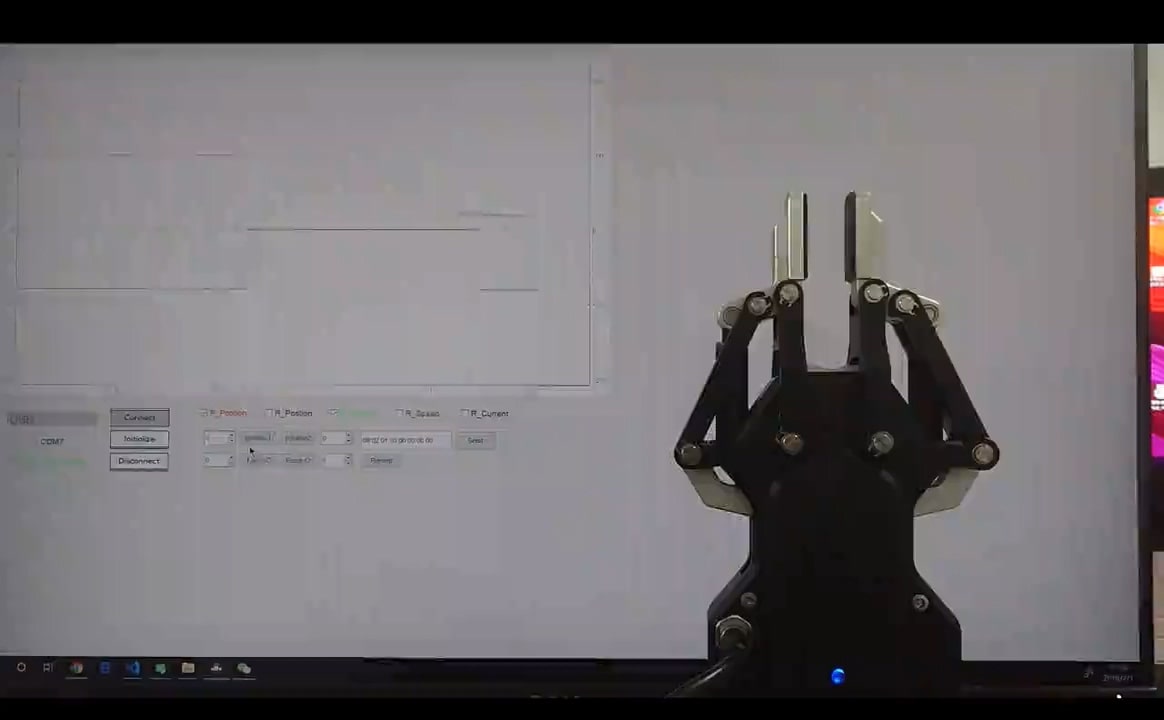

Now let’s shift gears to another twist in technology—the electric robot gripper. You know, the kind that makes automation seem effortless? With an electric robot gripper, it’s all about precision and functionality in diverse industrial applications. As industries evolve, the demand for these advanced systems only increases. They are designed to perform intricate tasks with unrivaled dexterity. Plus, as they embrace the digital age, you’ll find that they easily integrate with software systems for enhanced operational capabilities. It’s an investment that pays off!

Speaking of investments, let’s talk about industrial electric grippers. These bad boys are not just built for heavy lifting but are also adaptable to various environments—from automotive to healthcare. With their robust design and smart technology features, industrial electric grippers provide the stability and reliability your business needs. They minimize the risk of errors and optimize workflow, making them indispensable. The joined effort in automation results in faster production times and higher quality standards. Trust me, they’re worth the hype!

All in all, if you’re looking for a dependable manufacturer, consider DH-Robotics. They’ve got a solid reputation for providing top-notch electric grippers that meet various industrial demands. With supply advantages and a commitment to quality, you can be confident about your choice. Elevate your operations and watch productivity soar with DH-Robotics on your side!