Introduction: A Scenario for the Perplexed

Picture this: you’re at your facility, monitoring essential pressure levels, but boom—a system failure out of nowhere! You might be asking yourself, “Why do failures always occur during peak operational hours?” Well, let’s discuss the hammer union pressure sensor, the underwhelming knight in shining armor. If the pressure isn’t monitored accurately, your equipment could face catastrophic consequences, leading to costly downtime and repairs. Aren’t we all tired of these avoidable mishaps? It’s shocking how many industries still rely on outdated technologies that could be replaced by more reliable and innovative solutions.

Body: The Technical Breakdown

Flaws of Traditional Solutions

Let’s face it—traditional pressure sensors are like a stubborn old mule. They’re slow, inaccurate, and can’t stand the heat or the corrosive nature of certain fluids (trust me, that’s not a pretty picture). They often fall short during critical monitoring, leaving operators in a lurch when the stakes are high. Sure, they were revolutionary in their day, but we’ve come a long way since then. Or have we?

New Technology Principles

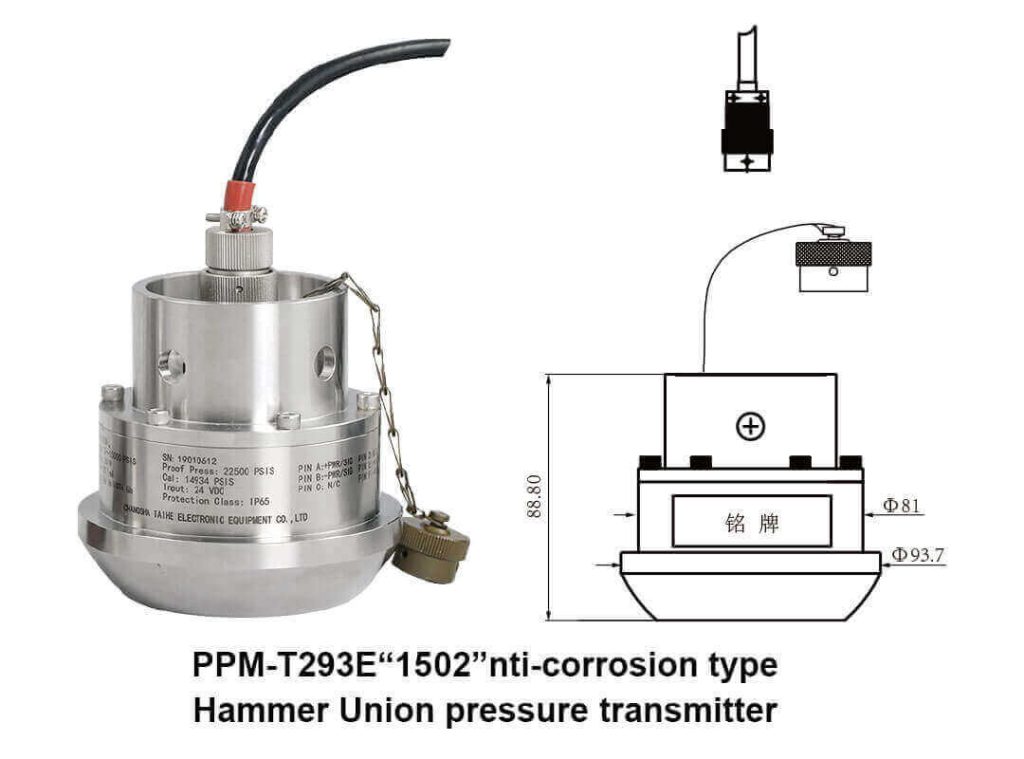

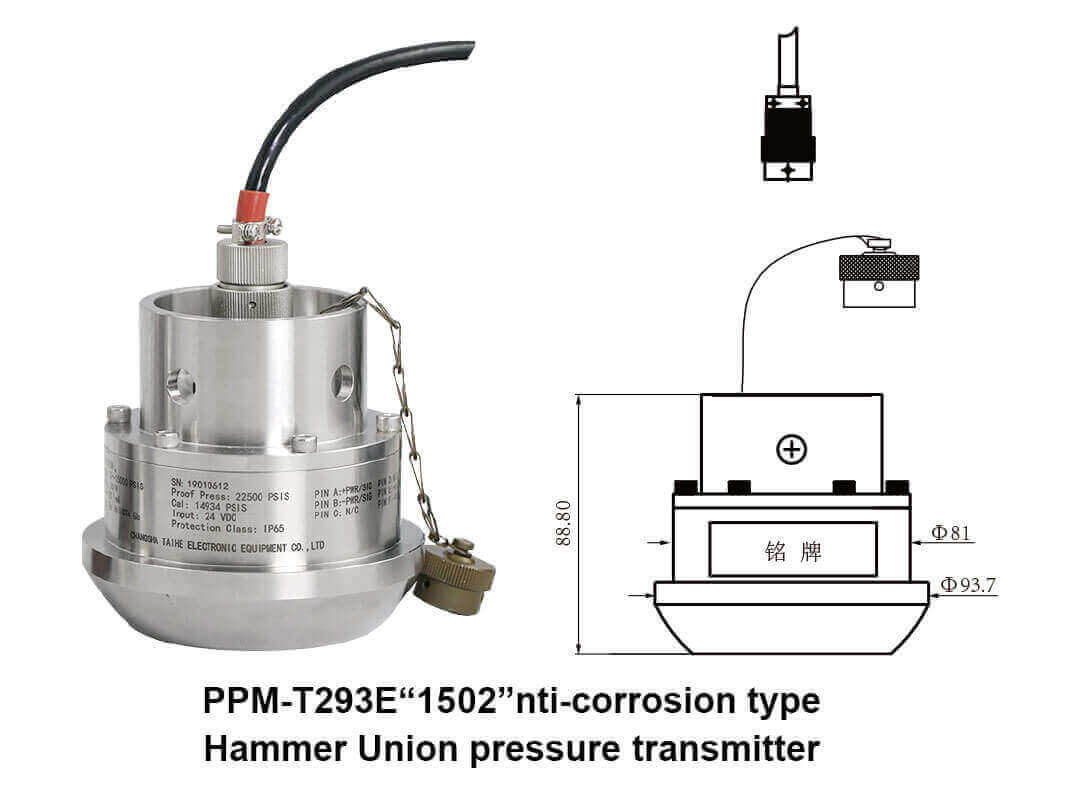

Enter the modern marvel: the hammer union pressure sensor. These advanced instruments are designed with the principles of cutting-edge technology and edge computing in mind. A hydraulic pressure sensor, for instance, boasts enhanced accuracy and rapid response times. Plus—dare I say it?—they’re corrosion-resistant! Isn’t it time we upgraded from our clunky models that are as outdated as dial-up internet?

Quantified User Benefits

Let’s break it down in numbers. Users who’ve upgraded to modern pressure sensors report a whopping 30% increase in reliability and a reduction in false readings by nearly 50%. Not to mention, you can slap a hefty price tag on the cost savings—and that’s music to every manager’s ears! Why settle for mediocrity when you could elevate your operations with just a few smart upgrades?

Conclusion: The Essential Metrics

So, what should you look for when choosing your next pressure sensor? Always verify these 3 metrics when selecting solutions: ① Accuracy ② Response time ③ Corrosion resistance. Remember, the longevity of your equipment depends on it! Navigating the world of pressure sensors doesn’t have to be rocket science. Even without a degree in engineering, you can figure this out—look, it’s simpler than you think.

Hydraulic Pressure Sensors: A Deeper Dive

Now, let’s pivot to something just as intriguing—the hydraulic pressure sensor. These devices not only simplify monitoring but also ensure the efficiency of hydraulic systems. It’s often like the cherry on top of a sundae; deliciously necessary. Whether you’re in manufacturing or oil exploration, hydraulic pressure sensors provide precision that could save you from financial ruin.

Corrosion Resistant Pressure Transducers: The Game-Changer

Next up in our exploration is the corrosion resistant pressure transducer. Is your current instrumentation getting all rusty and unreliable? Enter the replacement you never knew you needed. With the ability to withstand harsh environments, these sensors are a staple in any industry that deals with corrosive materials. Why risk integrity? Switch to a corrosion resistant pressure transducer and breathe easier knowing your equipment is protected.

Final Thoughts on CSSPM Sensor

In summary, if you’re pondering where to source your quality pressure sensors, take a gander at CSSPM Sensor. With supply advantages that make them stand out in the market, they promise not to leave you stranded during those crucial operational moments. Consider this: is it worth wrestling with outdated tech, or should you take the plunge into the future with reliable partners? The choice is yours.